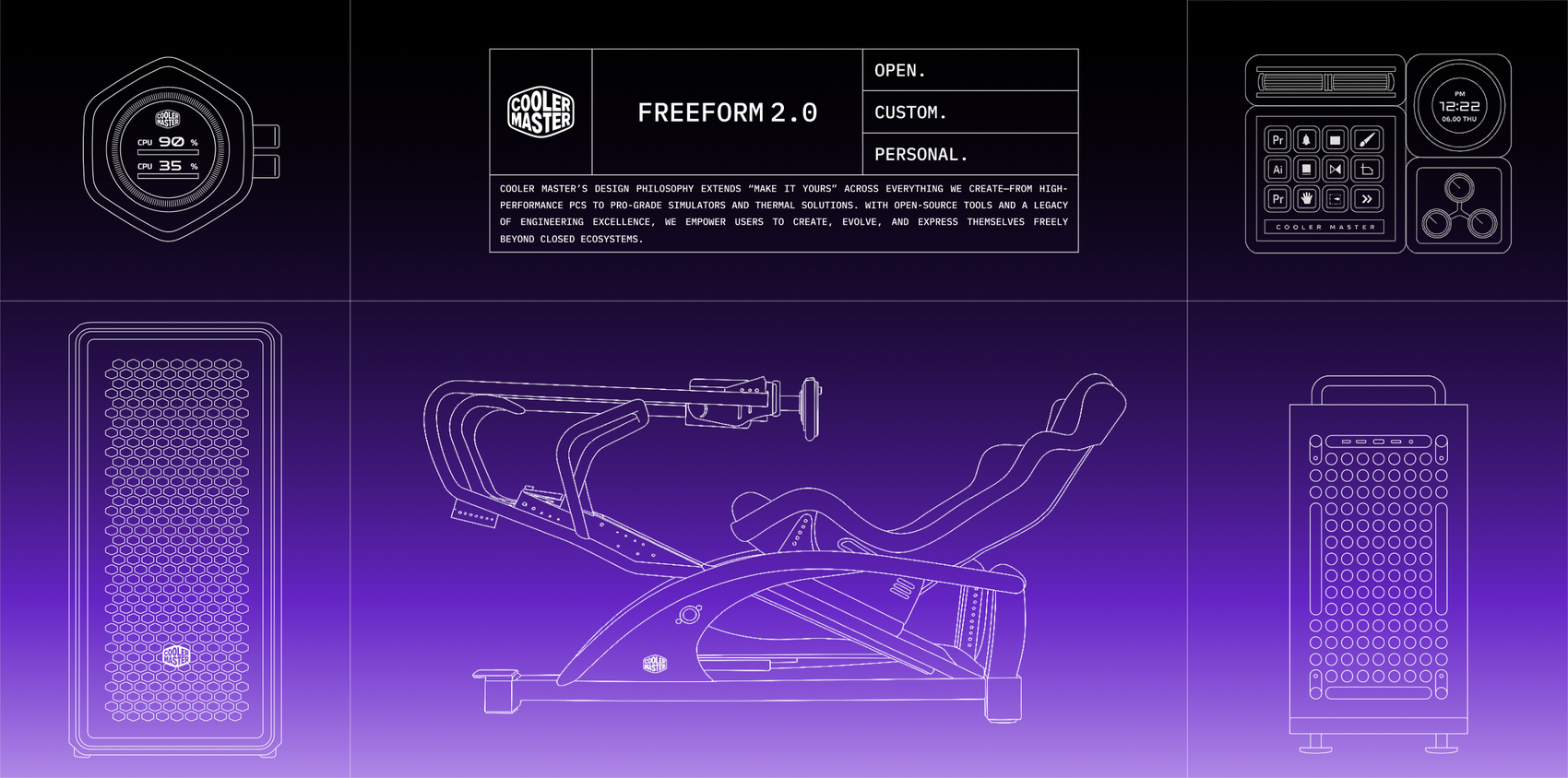

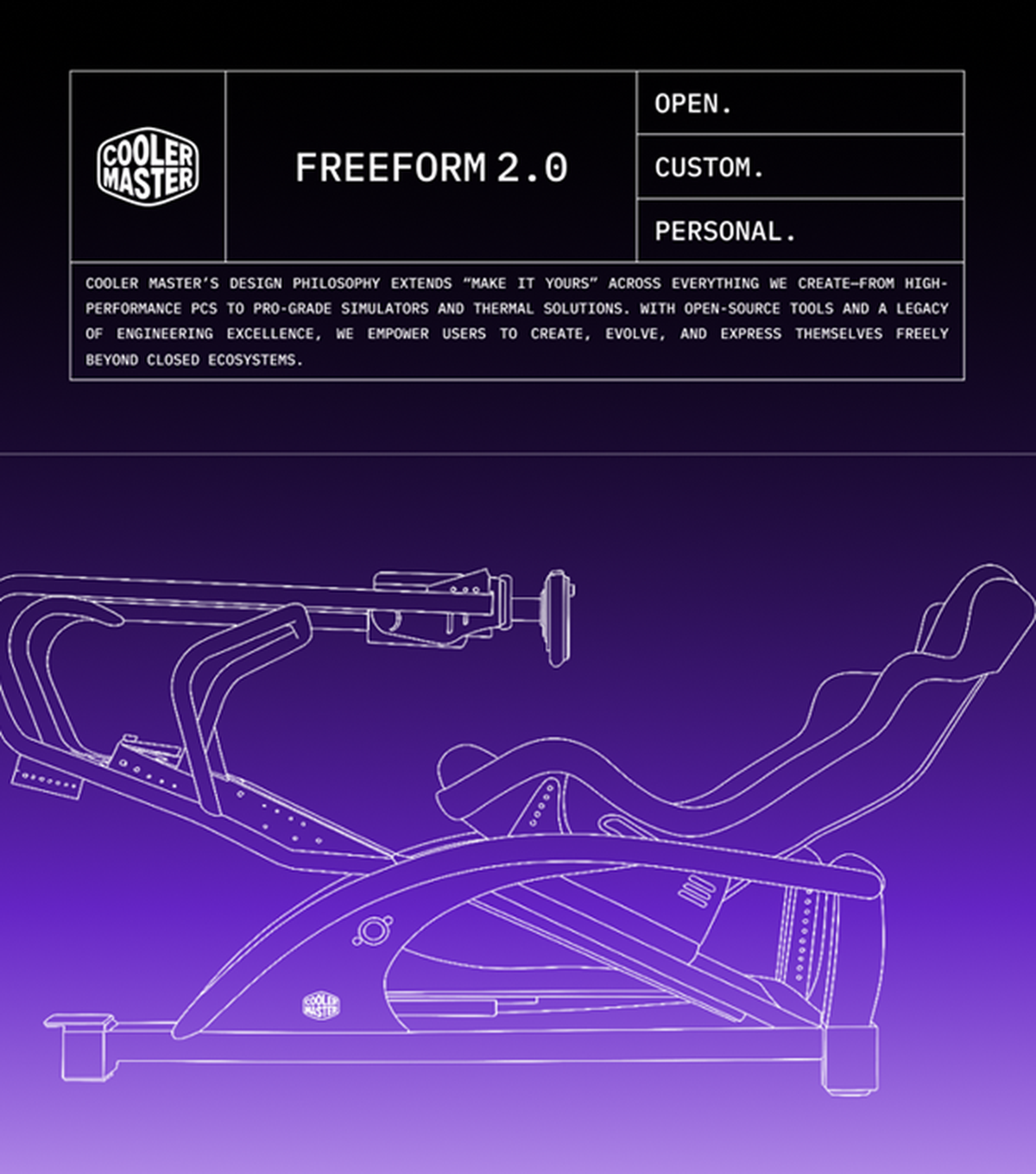

Customization means more when it’s built into the system. FreeForm 2.0 invites builders to create, remix, and refine their hardware with 3D-printed parts that integrate seamlessly into supported cases and accessories. It’s not just an option for modders. It’s a feature designed for anyone who wants to make their build more personal.

Customization means more when it’s built into the system. FreeForm 2.0 invites builders to create, remix, and refine their hardware with 3D-printed parts that integrate seamlessly into supported cases and accessories. It’s not just an option for modders. It’s a feature designed for anyone who wants to make their build more personal.

Open Access to Design Files

Cooler Master shares a full library of STL and CAD files on the FreeForm Open Source Files & Community Customization Page in partnership with Prusa, giving users a clear starting point for their own parts. These files are based on real product specs and have been tested for reliable integration, so there’s no guesswork when you want to print a replacement panel or design your own GPU support.

More advanced resources are also available. Developers can access SDKs and compatibility notes, making it easier to integrate electronics, sensors, or interactive elements into 3D parts without needing to reverse-engineer dimensions. These files are available in multiple formats, enabling easier collaboration between designers using different platforms or tools.

Cooler Master on Printables

The Cooler Master Printables page acts as both a download hub and a community platform. Users share builds, remix existing parts, and take part in seasonal contests that highlight creativity and design skill. Many of these designs come directly from the community, and Cooler Master regularly features them across official platforms.

Printables also offers full part previews, build instructions, and a rating system to help you choose which version works best for your setup. With thousands of users contributing, it’s easy to find inspiration, improve your ideas, or get feedback before printing.

This model supports shared innovation. Builders who want something unique can either print it themselves or use community feedback to refine their ideas before production. It creates a feedback loop between Cooler Master and its users, making each update more grounded in real-world creativity.

Built for Modders and Beginners Alike

FreeForm’s 3D integration doesn’t require specialized tools or engineering knowledge. If you can run a slicer and load a printer, you can build something that fits. You can even go to Prusa printing centers and have things printed for you. For new users, simple cosmetic parts offer a way to get started without risk. More experienced builders can push into more developed mods.

This layered approach gives everyone a path into personalization. You don’t need to commit to a full case mod to participate. You can build confidence project by project, expanding the level of customization as your skills grow.

Many users also find value in repairing or replacing small accessories instead of purchasing new hardware. Whether it’s a broken cable routing clip or a lost I/O shield, printing a part often takes less time than submitting a warranty request. And it keeps your system running without interruption.

Part of the FreeForm Philosophy

FreeForm supports 3D printing for the same reason it supports modular brackets and tool-free access: because the system should adapt to you. That means giving you the ability to change what you don’t like, enhance what you do, and build something that reflects your own identity.

It also means extending the useful life of your gear. You can replace damaged parts, build out missing features, or reconfigure your setup without starting over. The more you use it, the more it becomes yours.

Related Articles

• Modular Components - Evolving Your Setup Effortlessly