Tại Cooler Master, chúng tôi tin rằng làm mát tuyệt vời không phải là chạy theo điểm số benchmark, mà là sự tin cậy trong thế giới thực, kỹ thuật chu đáo và hiệu suất lâu dài. Thế hệ tản nhiệt chất lỏng mới nhất của chúng tôi có thiết kế bơm buồng kép tiên tiến, được xây dựng dựa trên nhiều năm nghiên cứu vật liệu, đổi mới cấu trúc và kiểm tra độ bền. Thiết kế này mang lại khả năng làm mát ổn định, hiệu quả trong suốt thời gian dài.

Tại Cooler Master, chúng tôi tin rằng làm mát tuyệt vời không phải là chạy theo điểm số benchmark, mà là sự tin cậy trong thế giới thực, kỹ thuật chu đáo và hiệu suất lâu dài. Thế hệ tản nhiệt chất lỏng mới nhất của chúng tôi có thiết kế bơm buồng kép tiên tiến, được xây dựng dựa trên nhiều năm nghiên cứu vật liệu, đổi mới cấu trúc và kiểm tra độ bền. Thiết kế này mang lại khả năng làm mát ổn định, hiệu quả trong suốt thời gian dài.

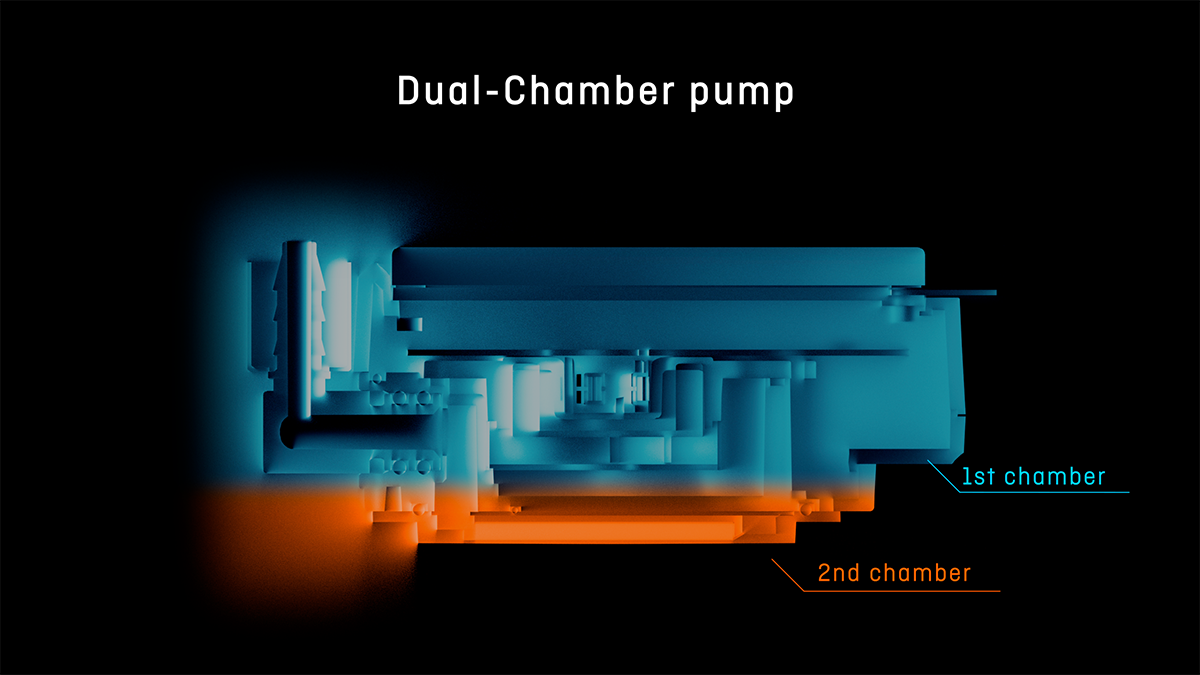

Ưu điểm của thiết kế hai buồng

Bộ làm mát AIO truyền thống dựa vào bơm một buồng, nơi chất làm mát chảy qua một không gian bên trong chung. Bơm hai buồng của Cooler Master áp dụng một cách tiếp cận khác bằng cách tách dòng chất làm mát thành các đường riêng biệt trong vỏ bơm. Sự tách biệt này ngăn chất làm mát nóng trộn lẫn với chất lỏng lạnh đi vào trước khi đến tấm đồng. Điều này giúp duy trì khả năng truyền nhiệt tối ưu. Kênh dòng chảy trung tâm dẫn chất làm mát hiệu quả hơn, giảm nhiễu nhiệt và hỗ trợ hiệu suất làm mát ổn định hơn.

Bằng cách cách ly cánh bơm khỏi stato động cơ, thiết kế hai buồng cũng giảm mức độ tiếp xúc nhiệt đối với các bộ phận nhạy cảm, góp phần kéo dài tuổi thọ tổng thể của bơm. Những cải tiến này làm cho bơm hai buồng đặc biệt hiệu quả đối với các hệ thống chịu tải liên tục, chẳng hạn như khi chơi game, render hoặc trong quy trình công việc chuyên nghiệp.

Thiết kế bơm mạnh mẽ hơn

Độ bền bắt đầu từ việc lựa chọn vật liệu. Bơm hai buồng của chúng tôi được làm từ PPS tổng hợp, được gia cường bằng 40% sợi thủy tinh để tăng 25% độ bền, cải thiện độ cứng và khả năng chịu nhiệt so với nhựa thông thường.

• Độ bền cơ học: Độ bền kéo trong khoảng 180–200 MPa, trong khi độ bền uốn đạt 250–280 MPa. Những con số này phản ánh khả năng của buồng đôi trong việc duy trì cấu trúc ngay cả dưới áp suất bên trong cao.

• Khả năng chịu nhiệt: Vật liệu có thể chịu được nhiệt độ liên tục lên đến 240°C, và đỉnh ngắn hạn lên đến 270°C. Điều này đảm bảo sự ổn định trong các phiên chơi game dài, khối lượng công việc chuyên nghiệp hoặc ép xung.

• Thiết kế cấu trúc: Buồng đôi bao gồm các gân bên trong xung quanh các khu vực lắp đặt quan trọng để tăng cường độ bền. Tường ngoài dày 3 mm và các gân gia cường hướng tâm giúp chống biến dạng do giãn nở nhiệt.

Mọi chi tiết của cấu trúc này đều được thiết kế để giữ hình dạng và tính toàn vẹn theo thời gian, ngay cả khi hoạt động ở mức hiệu năng cao.

Các linh kiện bền bỉ theo thời gian

Chúng tôi chọn các linh kiện bền bỉ. Mỗi bộ phận trong bơm hai buồng và hệ thống làm mát đều được tối ưu hóa cho vai trò của nó và được kiểm nghiệm để hoạt động dưới áp lực.

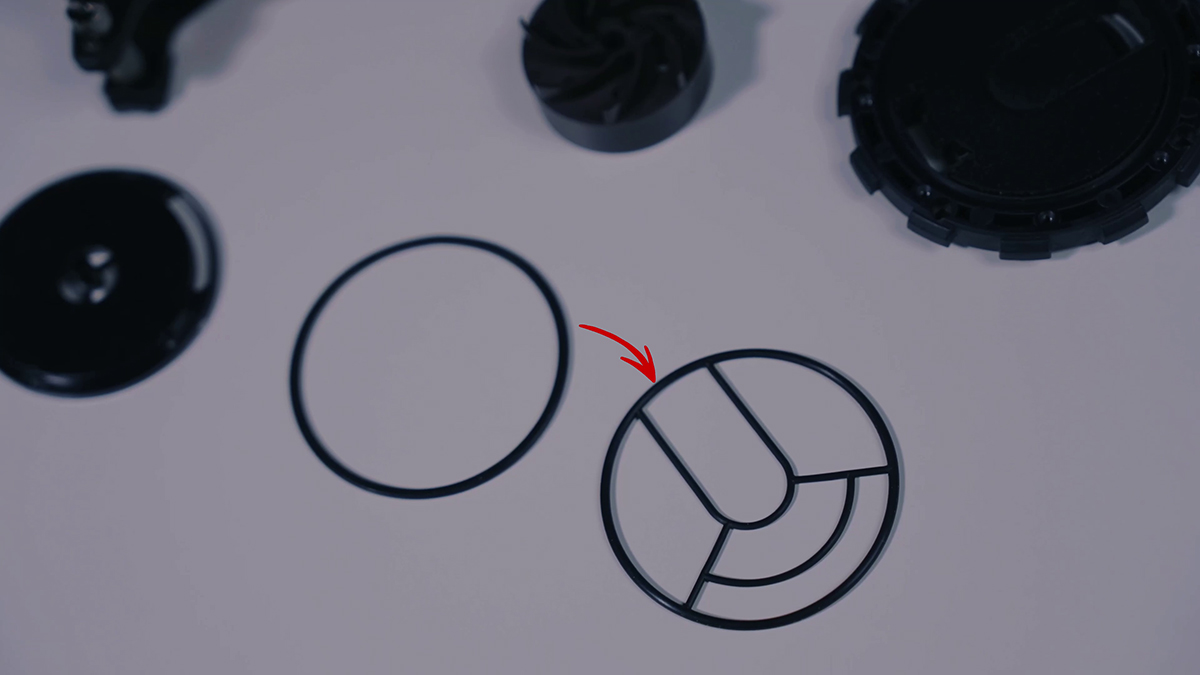

• Vòng đệm O-Ring: Vòng đệm sử dụng EPDM, một hợp chất cao su có khả năng kháng hóa chất và độ đàn hồi tuyệt vời. Nó vẫn dẻo dai từ -40°C đến 150°C, vượt xa phạm vi nhiệt độ của PC để bàn. EPDM cũng chịu được áp lực mà không bị biến dạng hoặc mất khả năng làm kín. Việc nó được sử dụng trong hệ thống ô tô khắt khe chứng tỏ rằng nó sẽ duy trì hiệu suất làm kín tốt hơn nhiều so với điều kiện vận hành của bộ làm mát PC.

• Trục bơm và ổ trục: Trục rôto bằng gốm, kết hợp với ổ trục sợi ngắn PPS+. Gốm có độ cứng cao và khả năng chống mài mòn, trong khi nhựa PPS mang lại đặc tính tự bôi trơn, giúp giảm ma sát và sự tích tụ nhiệt mà không cần bôi trơn bổ sung. Sự kết hợp này duy trì vòng quay chính xác trong điều kiện nhiệt độ thay đổi và tiếp xúc hóa chất, kéo dài tuổi thọ của bơm.

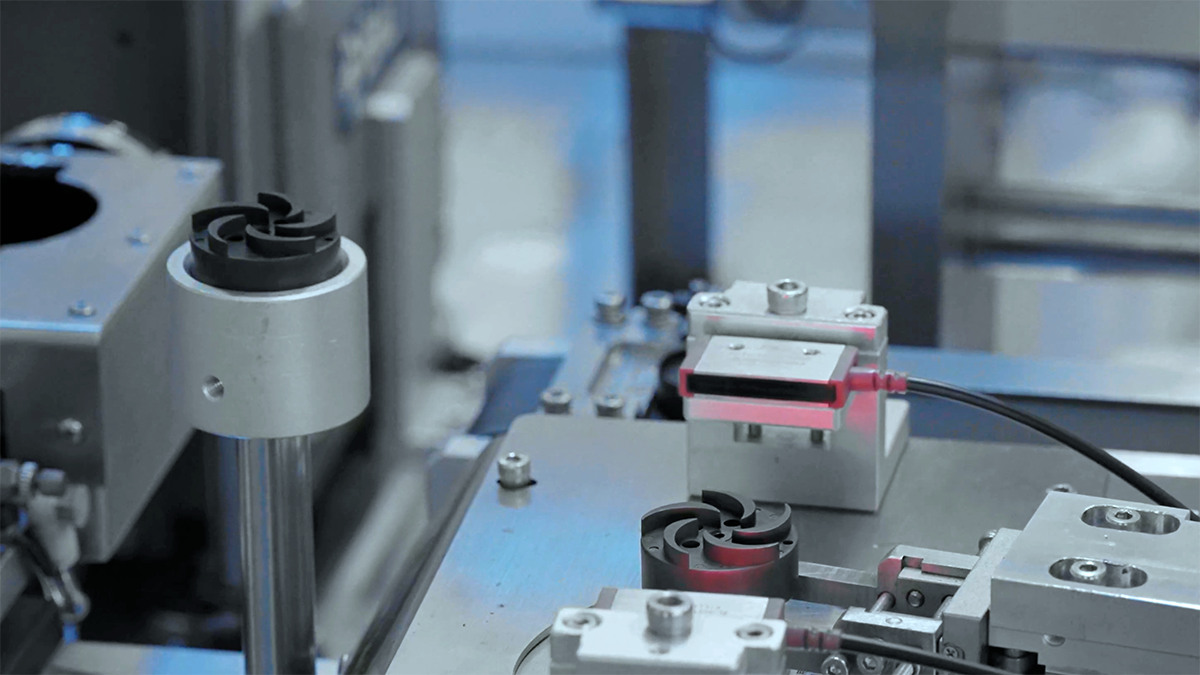

• Nam châm cánh bơm: Chúng tôi sử dụng nam châm nhựa ferrite đúc có khả năng chống khử từ, chống ăn mòn và mài mòn. Những nam châm này duy trì mô-men xoắn và độ ổn định quay trong nhiều năm hoạt động mà không cần lớp phủ hoặc gia cố bề mặt.

Mỗi bộ phận này đều được xác thực thông qua các bài kiểm tra căng thẳng thực tế. Chúng tôi đã thực hiện 2.000 giờ thử nghiệm nhiệt độ cao ở 88°C, sau đó tháo rời và kiểm tra. Không phát hiện thấy ăn mòn, biến dạng hoặc hư hỏng bên trong ở bất kỳ bộ phận quan trọng nào.

Ống dẫn hiệu suất cao cho thế giới thực

Hệ thống làm mát chỉ đáng tin cậy khi ống dẫn của nó tốt. Đó là lý do Cooler Master sử dụng hợp chất lai tạo từ EPDM và IIR. Sự kết hợp này mang lại độ bền vượt trội trước nhiệt, độ ẩm và áp lực vật lý.

• Chống nhiệt và lão hóa: EPDM chống chịu nhiệt, ozone và tia UV. Nó không bị suy thoái hoặc trở nên giòn theo thời gian, khiến nó lý tưởng cho PC và máy chủ.

• Khả năng làm kín và kiểm soát hơi: IIR cung cấp khả năng làm kín tuyệt vời chống mất hơi và bay hơi chất làm mát. Điều này giúp duy trì áp suất bên trong và giảm nhu cầu bổ sung thường xuyên.

• Hiệu suất uốn cong: Cấu trúc bện bên trong phân bổ lực khi uốn cong. Ống có thể chịu được hàng nghìn chu kỳ uốn mà không bị nứt hoặc rò rỉ.

Ống này được thiết kế để hoạt động trong các lắp đặt chật hẹp, môi trường áp suất cao và các hệ thống chạy liên tục.

Chất làm mát bảo vệ khoản đầu tư của bạn

Chất làm mát của Cooler Master là công thức cấp ô tô dựa trên cồn, tuân thủ các tiêu chuẩn toàn cầu chính bao gồm ASTM D3306 và SAE J1043. Nó cung cấp:

• Chống ăn mòn: Công thức ngăn ngừa ăn mòn điện hóa giữa các bộ phận kim loại hỗn hợp, chẳng hạn như đế đồng và bộ tản nhiệt nhôm.

• Hiệu suất nhiệt: Các phụ gia axit hữu cơ và muối vô cơ thúc đẩy truyền nhiệt đồng thời chống lại sự hình thành cặn và cặn lắng.

• Chất tăng cường bôi trơn: Chất làm mát bao gồm các tác nhân giúp giảm hao mòn bên trong bơm và cải thiện tuổi thọ tổng thể.

Chất làm mát này được lựa chọn không chỉ vì hiệu suất mà còn vì độ tin cậy trong vận chuyển, lưu trữ và các điều kiện nhiệt độ khác nhau trên toàn cầu.

Được kiểm chứng và tin cậy

Cooler Master xác thực mọi bộ làm mát thông qua thử nghiệm độ tin cậy kéo dài, sử dụng các mẫu đại diện trước khi sản xuất hàng loạt. Cụm bơm và tản nhiệt được kiểm tra chịu nhiệt liên tục 2.000 giờ ở 88°C. Mỗi mẫu được tháo rời hoàn toàn và kiểm tra để đáp ứng các tiêu chí sau:

• Tản nhiệt: Không đổi màu bên trong, không kết tinh hoặc oxy hóa tại các mối hàn.

• Buồng composite PPS: Không biến dạng, nứt hoặc ăn mòn vật liệu.

• Đế và lá tản nhiệt bằng đồng: Không bị sẫm màu, rỉ sét hoặc có cặn.

• Gioăng và ống EPDM: Không suy giảm vật liệu, bong tróc hoặc mất độ đàn hồi.

• Cụm cánh bơm: Không cong vênh, biến dạng hoặc dấu hiệu mỏi vật liệu.

Các thử nghiệm này là một phần của quy trình kiểm soát chất lượng tiêu chuẩn của Cooler Master, bao gồm kiểm tra kích thước, thử áp suất và phát hiện rò rỉ trong quá trình sản xuất và lấy mẫu sau sản xuất. Kết quả xác nhận hệ thống duy trì được tính toàn vẹn cấu trúc và hiệu năng vận hành ngay cả dưới áp lực nhiệt kéo dài, đảm bảo độ tin cậy nhất quán trong sử dụng thực tế.

Làm mát không thỏa hiệp

Thiết kế bơm hai buồng không chỉ là một thông số kỹ thuật, mà còn là tuyên bố về cam kết. Mỗi lựa chọn thiết kế, vật liệu và thử nghiệm đều phản ánh cam kết của chúng tôi trong việc xây dựng giải pháp làm mát bền bỉ. Từ vỏ bơm gia cường, vòng đệm chống hóa chất đến dung dịch làm mát hiệu suất cao, hệ thống này được tạo ra để phục vụ những người sáng tạo, game thủ và người lắp ráp cần nhiều hơn hiệu năng cơ bản.

Dù bạn đang ép khung hình trong game, render video hàng giờ liền hay chạy mô phỏng đa nhân, thiết kế bơm hai buồng của Cooler Master đều được tạo ra để theo kịp. Không thỏa hiệp, không chiêu trò tiếp thị, chỉ có khả năng làm mát đáng tin cậy và đã được chứng minh.

Đã đến lúc Make It Yours.

Tìm hiểu thêm về Làm mát bằng chất lỏng AIO của Cooler Master:

- Tech Dive: Teardown of MasterLiquid 360 ION Pump and Performance Comparison

- Tech Dive: Cut Open the MasterLiquid 360 ION Pump in Half to Show Its Leak Protection

- Tech Dive: The Secret Technology Behind The 6-year Warranty of MasterLiquid 360 ION