Less is More: It is time for the next innovation in CPU cooling: 3DHP

Less is More: It is time for the next innovation in CPU cooling: 3DHP

Heat pipes have been part of CPU cooling for decades. While materials and manufacturing have improved over time, the basic layout used in most air coolers has remained largely unchanged. As processors have evolved, that traditional approach has started to show its limits.

3DHP is Cooler Master’s response to those limits. Rather than simply increasing the number of heat pipes or relying on taller fin stacks, 3DHP focuses on how heat pipes are positioned, how they contact the base, and how heat is distributed through the cooler. The goal is consistent thermal behavior, lower noise and reliable performance under real system conditions.

This approach has now been independently tested by Cybenetics, confirming that 3DHP delivers balanced cooling performance with less noise and long-term reliability. Less really is more.

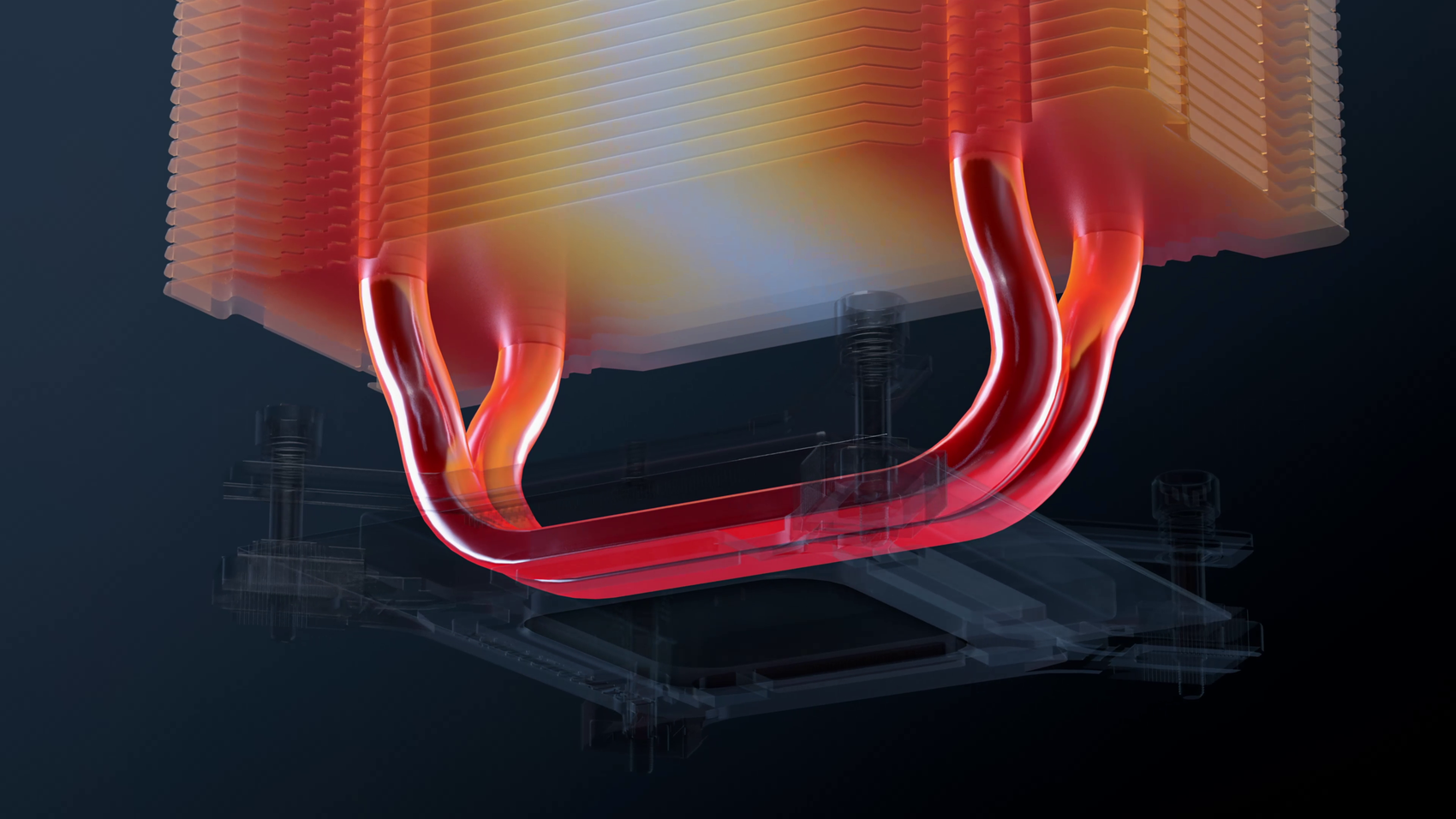

Rethinking Heat Pipe Geometry with 3DHP

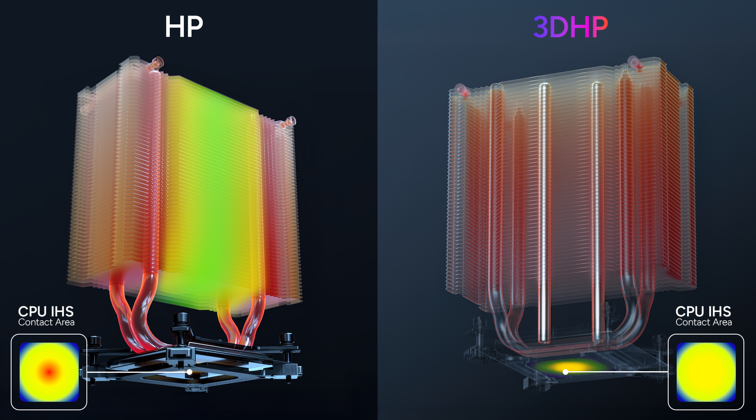

It all starts with the geometry of the heat pipe and its heat pipe layout. Most CPU coolers use two U-shaped heat pipes on either side of the cooler. This creates two opportunities: one is in the U-shape of the pipes and the other is in the mirrored placement of the heat pipes. Heat can pool in the middle of the U and between the two heat pipes.

Pooled heat is harder to cool. Fans have to spin up to their max rpm, causing noise and degrading performance over time. The cooler just isn’t as efficient of a design as it could be.

Why Traditional Layouts Fall Short

Traditional heat pipe designs tend to optimize for peak results in short benchmarks. In real systems, workloads fluctuate, ambient temperatures vary, and airflow conditions are rarely ideal.

3DHP addresses this by improving how heat enters and moves through the cooler, reducing the need for high rpms from the fan and helping systems remain quieter even when the workload increases.

The 3DHP Advantage

3DHP is designed around several pratical engineering advantages:

• Improved contact efficiency between the CPU and heat pipes

• Even heat distribution across the fin stack

• Better alignment between airflow and active cooling surfaces

Independent lab testing confirms these advantages by showing stable thermal performance with lower noise during extended use. Rather than chasing peak benchmark numbers, 3DHP prioritizes sustained efficiency and predictable outcomes.

Designed with Real Physics

Instead of assuming ideal conditions, Cooler Master engineered 3DHP around actual airflow behavior, real CPU load patterns, and practical system constraints like case orientation and memory clearance.

3DHP represents a shift in how air-cooling challenges are addressed. By focusing on heat pipe placement, airflow alignment, and sustained performance, Cooler Master has developed a solution that scales with modern processors and real-world usage demands.

In testing, the 3DHP layout delivers:

• Lower peak core temps in sustained workloads

• Smoother fan response curves

• Improved thermal recovery after load spikes

Independent Testing by Cybenetics

Cybenetics, an independent laboratory specializing in thermal and noise evaluation, tested Cooler Master 3DHP products to assess real-world performance and efficiency.

Testing shows 3DHP delivers higher thermal transfer efficiency per heat pipe compared to traditional heat pipe (HP) layouts.

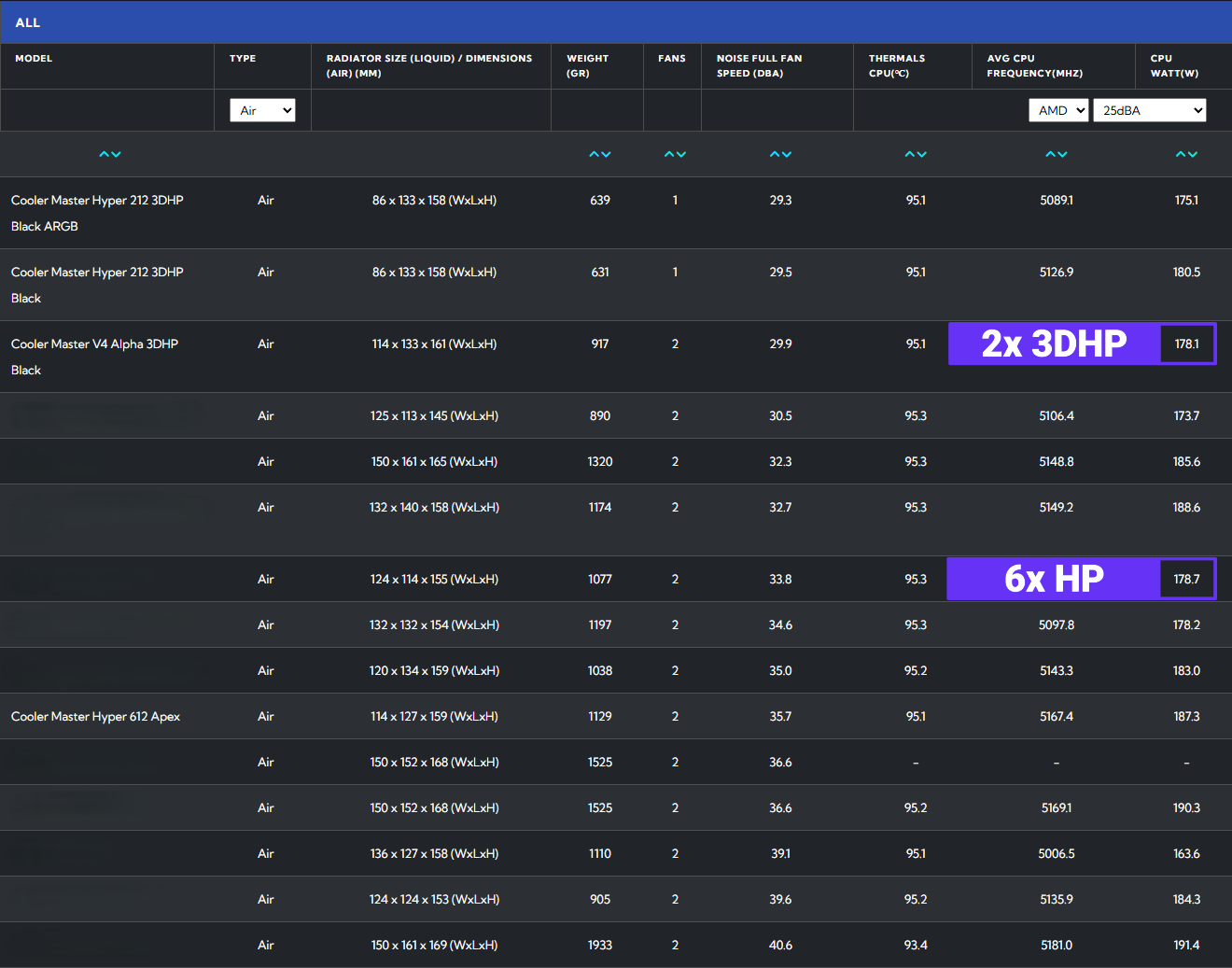

Performance per pipe (noise-normalized at 25 dBA):

| 3DHP | HP |

| up to 87 W per pipe | up to 34 W per pipe |

These results show approximately 2× higher performance per pipe under equivalent noise conditions.*

In addition to thermal efficiency, testing also shows less noise.

Source: Cybentics

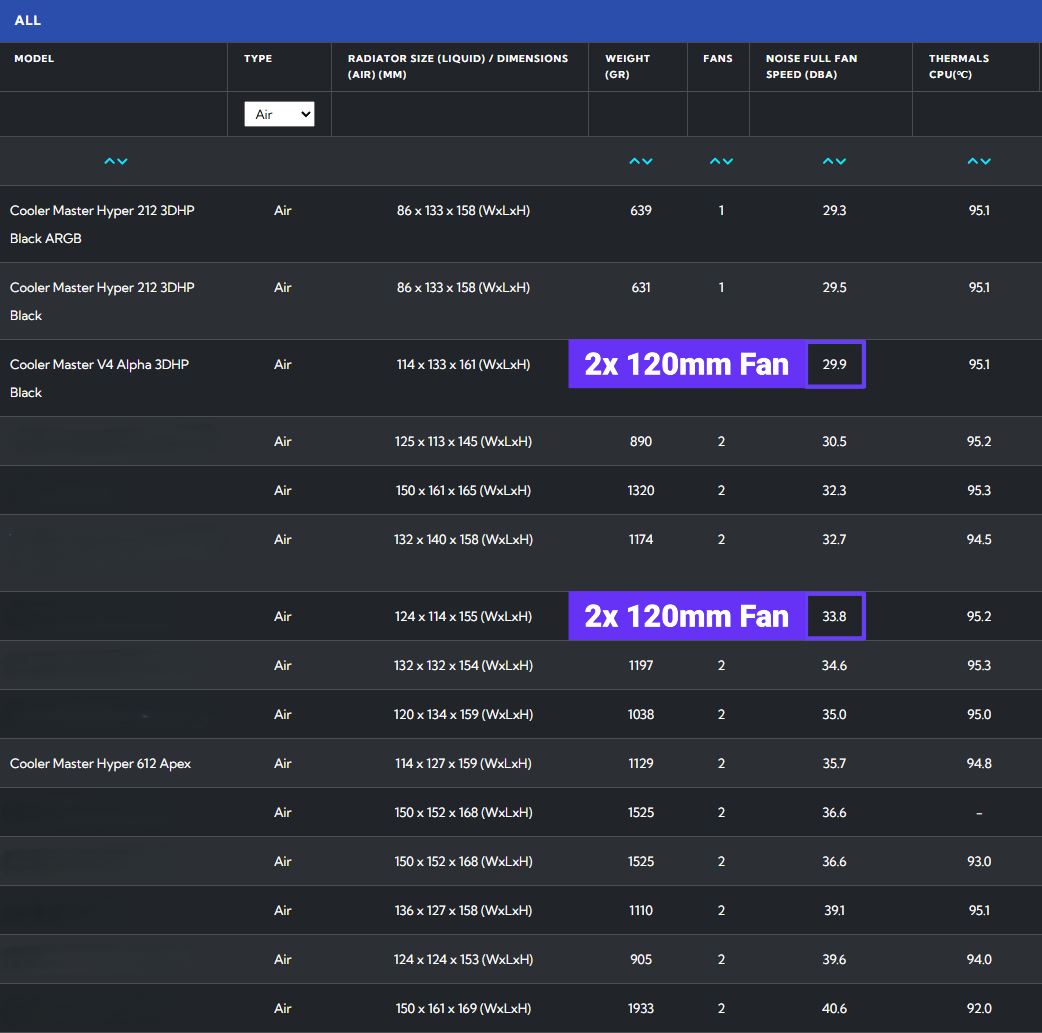

Noise Performance (identical maximum fan speed using two 120 mm fans):

| 3DHP | HP |

| up to 29.9 dBA | from 33.8 dBA |

This represents approximately 35% less noise in equivalent airflow conditions.**

Source: Cybenetics

* Performance difference recorded at 25 dBA noise-normalized testing

** Noise difference recorded at identical maximum fan speed using two 120 mm fans

Cooler Master’s Thermal Expertise

Cooler Master took a novel approach to create this innovation. 3DHP was engineered by first observing and testing how heat is created and how it moves in modern PC systems. Our engineers made discoveries that went beyond theory, than set about to solve problems they uncovered and created the next big change in cooling.

Discover the current lineup of 3DHP Air Coolers by Cooler Master here.